In our previous article, we discussed: 'How to select the correct cable size for 1 phase.' In this article, we will discuss on how to pick the correct cable size for 3 phases. 3-phase voltages are usually used for multiple story buildings such as hotels, apartments, malls, factories, etc. The standard voltages used in a 3-phase is 380 volts. How did we get the number 380 volts? To explain this further, let’s go over the following review:

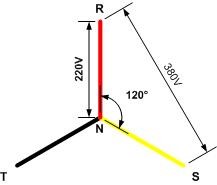

A 3-phase voltage is represented by three lines with one end meeting one another, causing every line forming an angle of 120º. That angle is what differentiates between one phase and another of 120º. For more details, you may view the following figure.

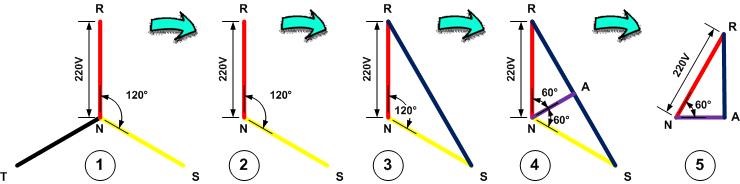

To find out where the number 3 comes from, let’s use a simple mathematical equation with the help of the following figures:

You can see an explanation of the figures above in the following description:

Figure 1: Representation of the 3-phase and neutral voltage, where the phase-to-neutral voltage is 220 V (VRN=220 V, VSN=220V, VTN=220V).

Figure 2: A sample of two phases, where between the two different phases is an angle of 120º.

Figure 3: Drawing a line from R to S, which represents the inter-phase voltage or VRS.

Figure 4: The area of the RSN triangle is divided in half by drawing the line NA, creating two identical triangles, with the angle RNA = angle SNA, of 60°.

Figure 5: A triangular piece of RNA from Figure 4. From this figure is where the calculation will begin.

Remember this equation to calculate the feet of the triangle. Referring to Figure 5, we can obtain the following formula:

From the calculation above, we may refer back to Figure 4, RS = RA + AS, and RA = AS making RS = RA + RA or RS = 2RA, which equates to:

VRS = 380 Volt

The following also applies to VST and VTR.

Before calculating power, make sure you know the capacity of the electric appliances beforehand.

For example, PT. Wilson Surya Unggul has a clean water pump of 7.5 kW, how much is the amperage?

Notes:

I = Ampere

P = Power (Watt)

V = Voltage (220 V)

Cos Ø = 0.8

= 1.73

From the following ampere, we are required to use cables with a greater current-carrying capability of about 125% as a safety factor.

After knowing the amperage with the safety factor, the size of the cable can then be determined according to the current-carrying table below:

NO Cross Section mm² Amperage

1 0.75 mm² 12 A

2 1 mm² 15 A

3 1.5 mm² 18 A

4 2.5 mm² 26 A

5 4 mm² 34 A

6 6 mm² 44 A

7 10 mm² 61 A

8 16 mm² 82 A

9 25 mm² 108 A

10 35 mm² 135 A

11 50 mm² 168 A

12 70 mm² 207 A

13 95 mm² 250 A

14 120 mm² 292 A

Then we can choose the cable that has the current-carrying capability of 17.82 A, which is the cable with the cross-section of 1.5 mm2.

Below is a table with examples of calculating 3 phase with the known kW:

NO KW Voltage Ampere Safety Factor 125 % Cross Section Cable

1 4KW 380V 7.61A 9.51A 0.75 mm²

2 5.5KW 380V 10.46A 13.07A 1 mm²

3 7.5KW 380V 14.26A 17.83A 1.5 mm²

4 15KW 380V 28.52A 35.65A 6 mm²

5 18.5KW 380V 35.18A 43.97A 6 mm²

6 022KW 380V 41.83A 52.29A 10 mm²

7 30KW 380V 57.04A 71.30A 16 mm²

With the steps above, you can now decide the size of the cables to use and also how to apply them in daily life. Don’t forget to also use the right cables based on your needs to match with its capabilities as well.

For cable products, choose Wilson Cables with its array of benefits and capabilities such as 3x faster to extinguish, made of 99% pure copper, easy application and labels printed with digital marking.

Other Interesting Information:

1. How To Determine The Right Cable Size For 1-Phase!

2. The Differences Between Phase, Neutral and Grounding Power Cables

3. Understanding the Difference Between Medium Voltage and Low Voltage

4. Why Are High-voltage Cables Installed a Little Loose?

5. Get to know 5 Kinds of Electric Voltage Measuring Instruments